There comes a time in everyone's life when they need to drill holes in a piece of metal in a rectangular pattern. The trick is to get them lined up evenly. I decided to document one technique here in case I ever forget how I did it.

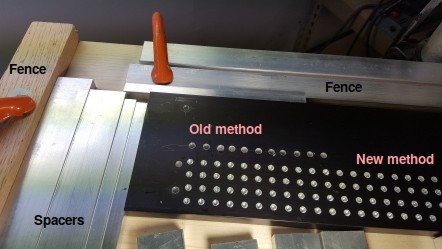

Clamp a flat piece of wood at least twice as big as the piece you want to work on to a drill press so it cannot move. Clamp a metal or oak fence on two sides as shown in Fig. 1.

Cut spacers from a square aluminum rod to match the desired spacing. If you need more than 3 or 4 rows, create more spacers 3 times the desired spacing. To make a 1×1 cm grid, I used spacers 1×1 cm and 1×3 cm and about six inches long.

Use a countersink bit, not a regular drill bit, to avoid wandering.

Align the piece in the corner, drill a pilot hole, then start adding spacers on the left.

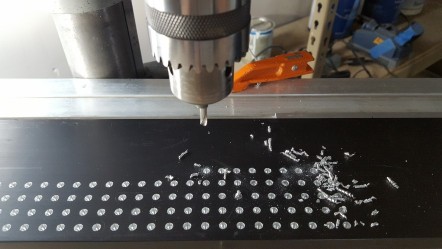

For the next row, add spacers along the top (Fig. 2). Manually push the piece tightly against the spacers before drilling, making sure there are no chips in the way. Even a small chip will cause you to drill in the wrong spot.

If you run out of spacers, use two deep throat C-clamps to clamp the most recent spacer in place.

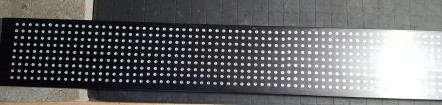

Fig. 3 shows the final result. Compared to the 'old' method of measuring, marking, punching, and drilling, seen in the top row of Fig. 1, it is much faster and produces better results. I ended up filling that top row with epoxy.

Each pilot hole took about 8 seconds. To drill all 783 holes took over two hours. (Maybe I got carried away with the number of holes.) The result is not nearly as good as what a professional would do: one was off by almost half a millimeter due to chips that I didn't notice.

Most professionals would probably use a CNC to do this. And no professional would ever use wood--if you get cutting fluid on the wood, it could cause problems. In fact, a real machinist would probably get fired on the spot for using this technique.

Drilling in aluminum

It can be tricky to drill holes in aluminum. If you drill at the normal speed, chips get wrapped around the drill bit, forcing you to stop and clean it constantly. The bit can even get stuck, causing it to break. I'm not an expert, but the trick seems to be to set the drill press to a much higher speed (1720 RPM instead of 620 RPM, or 74.75 ft/min with a 0.166 inch diameter bit) while keeping the feed rate the same. This causes the chips to be thinner so that they break into small pieces. I also soaked a piece of soft wood in cutting oil and pressed it against the bit to help break up the chips. Spraying WD-40 into the hole also worked, but was a bit messier.

The higher speed makes drilling more dangerous, and goggles are essential. The high speed also imparts more kinetic energy to the chips, causing them to be flung off the drill bit, which is good. But you have to clear the area of anything electrical before starting, and I found myself picking small pieces of aluminum out of my clothes and hair for the next hour. On the plus side, pecking (the usual solution for aluminum) isn't needed.

may 03 2022, 7:04 am

Fig. 1.

Fig. 2.

Fig. 3.