How to Repair Broken Eyeglass Frames

Here's the procedure for repairing metal eyeglass frames.

This will take about 5 minutes for the actual repair, 10-15 minutes

to polish the metal, and about six hours to find the screws to

reassemble the eyeglass frames.

The cost of the materials is about the same as the cost of having

a single repair done by a professional. If your glasses break more

than once, repairing it yourself as shown here will be cheaper than

taking it to a repairman.

January 1, 2004; updated Apr 05, 2020

|

1. Soldering

- Clear some space on your workbench, like this.

This will make it much easier to work.

- Assemble the supplies.

For all practical purposes, it's impossible to create a

strong joint by butting the two ends together by soldering.

Therefore, we will use a small piece of metal to reinforce

the broken area. The ideal thing to use is a short

piece from an old pair of glasses, ideally made of

the same metal. Alternatively, part of a metal bobby

pin, piano wire, or any other flat piece of spring steel,

may be used. Most eyeglasses are made of silver-nickel or

gold-plated steel, which are easy to solder.

Nowadays, more and more eyeglass frames are made of titanium.

Titanium is probably the best metal for eyeglasses because it's

42% lighter than steel and has the same thermal expansion coefficient

as glass. However, titanium is impossible to solder. Titanium is

usually alloyed with vanadium and aluminum, which make the alloy

stronger. Titanium, vanadium, and especially aluminum form surface

oxides that make it difficult for solder to adhere to them. They

must be brazed or welded.

Some other types of eyeglass frames are too springy to solder

effectively. The problem here is that the solder is not as flexible

as the underlying metal, and the joint eventually works loose or

cracks when the frames are flexed too many times. These

frames must also be brazed or welded (see below).

You also need a two-inch piece of 24-gauge copper wire.

-

Unscrew the side-arm from the frame. If it can't be unscrewed,

carefully remove the lenses and place them aside. Remove the

plastic earpiece so it doesn't get burnt. Use sandpaper to

thoroughly clean both pieces. Touch the pieces only with

forceps, not with your fingers. Grease from your fingers, dirt,

corrosion, or any coating on the metal will result in a

weaker joint or prevent the pieces from sticking.

The side-arm in this example was not completely broken,

but contained a weak area at the point where the metal

becomes narrow. This made it possible to use a single

clamp instead of two clamps.

- (Optional) Use a file to cut some diagonal grooves or

shallow scratches on the inside face of the small

reinforcing piece. This will create a small space between

the parts so the solder can flow between them and act as

a glue, which will make the repair stronger.

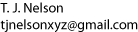

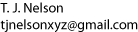

- Clamp the reinforcing piece to the inside of the broken

arm using one or two small alligator clips (available from

electronics stores). Wrap the copper wire around

both pieces to hold everything together.

- You will need some silver core solder, flux, and

a lighter. Make sure the solder and the flux both

say "lead-free". The temperature of the torch is high

enough to evaporate lead. If you use solder that contains

lead, not only will the repair not work, but you and

everyone in your house will also get serious lead poisoning.

If your eyeglass frames are made of gold-plated metal, use

gold solder (available from a jeweler's store or various

Internet sites) instead of silver solder if you want the

colors to match.

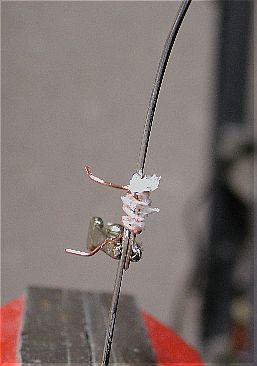

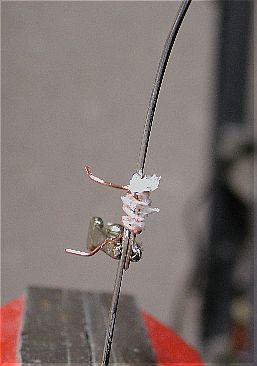

- You will also need a propane torch. Keep it far away

from flammable solvents like acetone, as shown here.

Naturally, a smaller torch would be better.

- Put some flux on all sides of the assembly. The amount

shown here is more than is needed, but excess doesn't

cause any harm. The flux prevents oxygen from oxidizing

the metal, which would prevent the pieces from sticking.

- Heat the assembly for about 1 second, touching solder

to the top part. Keep the solder behind the assembly to

minimize direct exposure of the solder to the flame. The

solder will be melted by the metal and will be sucked between

the pieces by capillary action. The clamps can be removed if

desired to prevent them from being ruined by the solder.

Warning: don't heat near a joint. Many frames

are held together by brazing and heating it will cause

the pieces to come apart.

- If the piece is not entirely covered with solder,

remove the copper wire and add the clamps above and

below the soldered area. Add more flux and apply the

flame again. The piece should be completely and evenly

covered with solder. If the copper doesn't come off,

cut the ends and leave it in place.

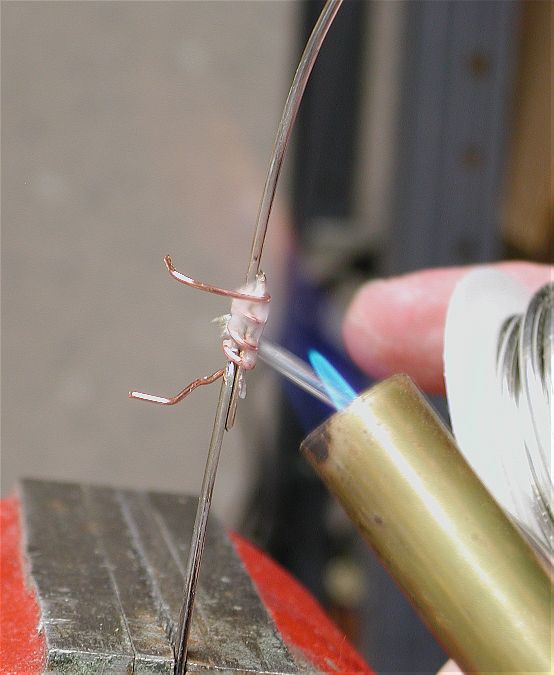

- Remove any rough edges or leftover copper wire with

a file and sand the metal first with 220 grit alumina

sandpaper, then with 600 grit sandpaper.

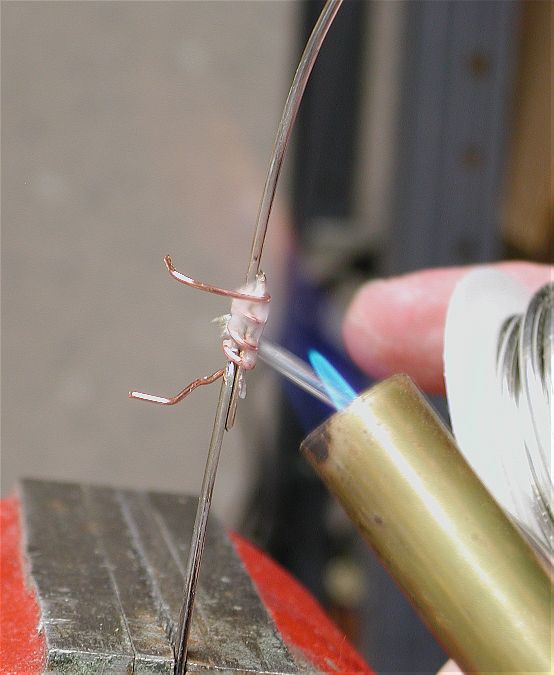

The piece should look like this, with a convex bead

of solder at both ends of the piece. There shouldn't

be any solder on the outside of the piece. Once this is

polished, the reinforcing piece will not be noticeable

from the outside.

- If desired, the metal can be polished using the

items shown here: a buffing wheel, a stick of polishing

compound (left), and high-gloss polishing compound.

Note the goggles, which are essential during this step.

A Dremel tool with a small buffing wheel can be used

instead of a buffer; however, only use the lowest

speed on the Dremel tool, otherwise the piece will

heat up and ruin the joint.

Polish the end of the eyeglass arm so the plastic earpiece

easily slides back. Thoroughly clean everything before

touching your lenses. The buffing compound will easily

scratch plastic as well as glass lenses.

Update: I found that hand-polishing with a product

called Mother's Aluminum Polish works even better.

2. Brazing

Eyeglass frames can also be repaired by brazing. Brazing produces

a much stronger repair than silver solder. Your eyeglasses will be

almost indestructible.

The supplies that are needed are:

- A propane torch. A propane-air torch can heat small items to

a high enough temperature to melt brazing rod. For larger

items, you would need to use something hotter, such as

propane-oxygen, MAPP, MAPP/oxygen or even acetylene.

But propane/air is ideal for very small items. The MAPP

torches available in hardware stores are often useless,

because they only have two settings: ``off'' and ``incinerate''.

- Brazing rod. There are many types of brazing rod, including:

- Bronze brazing rod -- for steel, cast iron, copper

base metals, but not stainless steel. Tensile strength = 60,000 psi.

Working temperature

= 1620°F. This type is slightly easier to work with and

has a yellowish color useful for gold parts. White flux coating.

- Nickel silver brazing rod -- for carbon and alloy steels

including stainless steel

as well as non-ferrous metals. Tensile strength = 85,000 psi.

Working temperature = 1680°F. This type is stronger and

has a silver color. Blue flux coating. Silver brazing rod is more

expensive but flows into cracks better than bronze. Be sure

the rod does not contain cadmium. Requires a higher-temperature

torch in order to melt.

- Aluminum brazing rod -- suitable for brazing aluminum.

Working temperature = 750°F.

- Proprietary alloy brazing rods are available with tensile

strengths up to 100,000 psi.

- Phosphorus copper brazing rod -- suitable for copper and

copper alloys. Tensile strength = 40,000 psi. Working temperature =

1450°F. This type is easily melted by a propane torch.

The most convenient is the type that is coated with flux.

A smaller diameter rod is preferred when using a propane

torch, because it's easier to melt.

- A hands-free clamp.

Procedure

- Disassemble the part as much as possible to avoid damaging

the lenses or any small screws.

- Clean all the parts with a wire brush. Make sure the

metal does not contain any toxic coatings, such as lead,

cadmium or zinc. If the metal is galvanized, brazing should

be carried out in a fume hood.

- Clamp the parts into position using a hands-free clamp.

Leave a very small gap (less than 1 mm) between

the pieces to allow the metal to flow into.

- Heat the brazing rod first until the flux starts to melt. The flux

should flow over the parts as a clear watery liquid.

- Next heat the parts until they are orange-hot.

If the parts cannot be made hot enough to appear orange, they

are too big. If you clamp it too closely to a large metal

object like a vise, it will conduct heat away too fast,

making it impossible to heat to a sufficient temperature.

- The brazing material will eventually melt and be sucked between

the parts by capillary action. The hottest part of the flame

is the clear area just beyond the inner blue flame. The blue flame

itself should not touch the metal.

- Wait for the parts to cool in air several minutes before cooling

with water.

- Remove the flux by sanding or wash in 30% sulfuric acid.

- File any rough edges and polish it.

The disadvantage of brazing is that heating steel to this

temperature can weaken it. For example, heating a spring is likely

to cause it to lose its springiness. Clamp something solid around

the piece to prevent heat from being conducted to any screw holes

or springs. Be careful not to heat near brazed joints (such as the

nosepiece) or the existing joint may come unbrazed.

Also, the metal should be heated just enough to make

a good bond. This is not a major problem for the titanium or

silver/steel alloy used in most eyeglass frames, because tensile

strength, resistance to bending, and modulus of elasticity

(springiness), are more important than hardness. For other

types of steel, the rate at which the steel must be cooled

depends on the type of steel and the properties needed.

Some grades of steel have to be quenched in a salt or oil

bath or annealed by gradually lowering the temperature.

Carbon steel can also decarburize at high temperatures, which

will reduce its hardness.

Needless to say, brazing should always be done in a well-ventilated

area. Avoid heating brass, which can release zinc fumes. Brazing small

parts, unlike welding, does not release significant amounts of

carbon monoxide. Avoid brazing rods containing cadmium.

3. Welding

The ideal method for repairing eyeglass frames, especially those

made of titanium alloy, is welding. This requires special equipment

similar to that used by dentists. Welding is beyond the scope of

this document.

Update (Nov 28, 2010)

Ilia Jerebtsov writes that silver soldering did not work for

his eyeglass frames. It seems that some types of metal are too

flexible for the solder to stick. However, he was successful with brazing:

A micro-torch, even though the box says it has a flame temp of 1300°C,

won't melt brazing rod, I found out. Apparently the working

temperature is much more important and is often not mentioned. In the

end I successfully used a nickel silver rod with a 1700°C flame / 650°

working torch. It took me just a couple of seconds and about half a cm

of rod to do it.

Something worth noting is that if the frames are half-rimmed, like

mine, the lenses are secured by a nylon string that goes through

little holes. I had to re-drill them after the brazing. I used a 1mm

bit with my Dremel. It's not very hard with the precision attachment

and a magnifying glass. Also, fishing line is a perfectly good

replacement for the string. I was under the impression that you need

some kind of secret glasses wire that only opticians have, but nope,

it's just fishing line.

Update (Apr 05, 2020)

More information on brazing titanium

As noted above, it's impossible to solder titanium—you have to braze it.

I haven't tried brazing titanium myself, but there are now special fluxes

designed for brazing titanium, such as from

superiorflux.com.

This site has pointers on the correct temperature, which is very important.

The flux is supposed to protect it from oxygen. If your titanium oxidizes,

nothing will stick to it and it might even burn.

An alternative is to do the brazing in a welding box filled with argon.

The biggest challenge with eyeglasses is the bridge. Eyeglass frames are

usually made by brazing to start with, so if you heat up one side of a bridge

piece, quite often the heat gets conducted to the other side and you end up

with three or more pieces. This is not to say it's impossible, but you'd need

to take certain precautions before starting:

-

Remove the lenses and any screws and store them in a safe place. Some

frames also contain tiny springs. If the heat from your torch reaches a

spring, the spring can lose its springy properties. There are often also

tiny metal parts which will fly out and get lost when you remove the spring.

Make a diagram and wear goggles.

-

When brazing, 99% of the work is setting it up in a frame and clamping

it so nothing can move. If you're going to do a bridge, you'll need to

clamp some kind of heat sink (aluminum or copper are best) on

it to protect the nose pad and the other side of the bridge. If anything

moves while you're brazing it, your frames will be crooked.

-

If you've never brazed titanium before, buy some titanium from McMaster-Carr

and practice first.

-

The brazing material looks to me like ordinary silver solder.

People used to say brazing aluminum was impossible. Now it's routine.

Flux for brazing aluminum is available and I've brazed aluminum many

times.